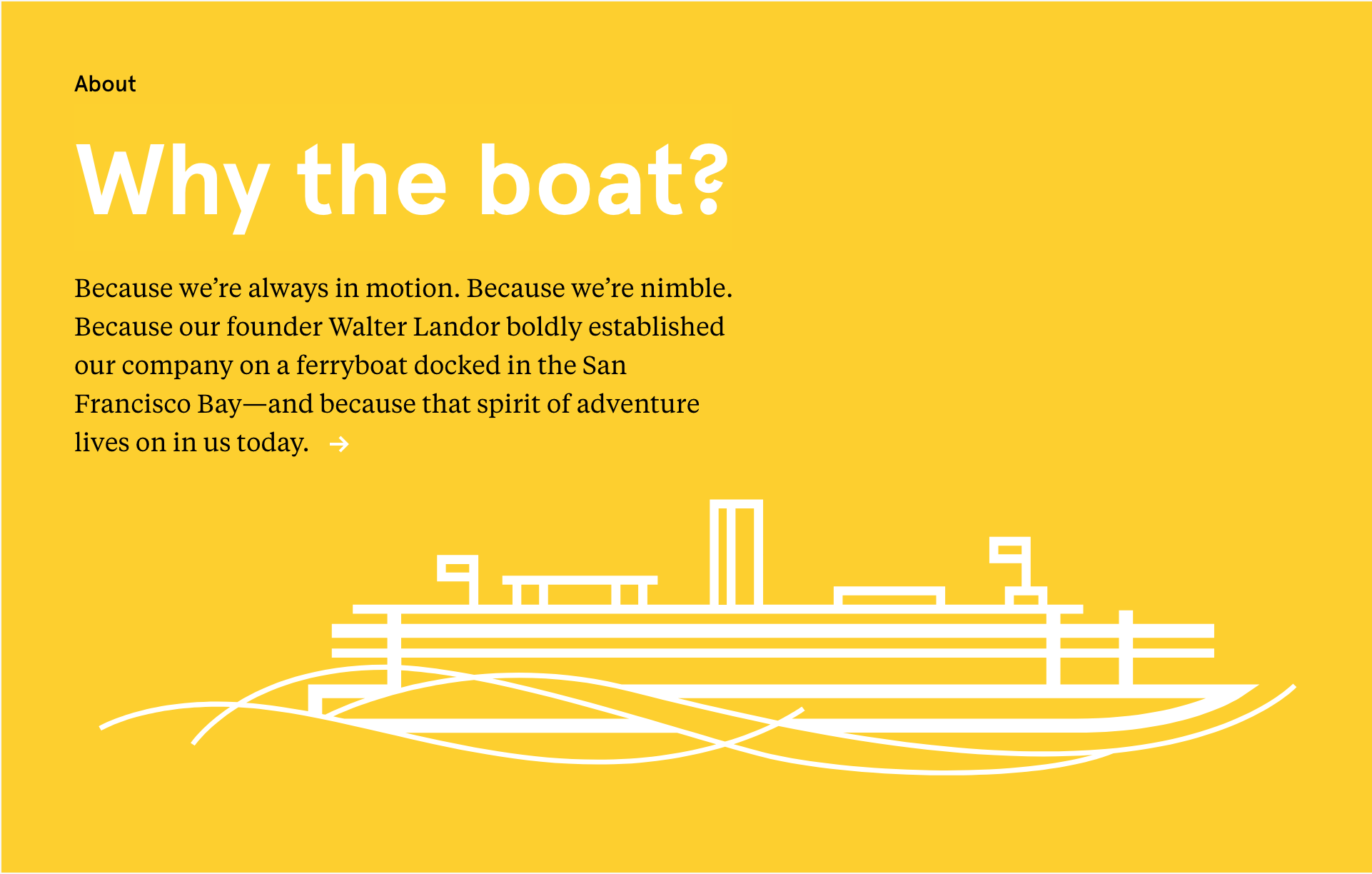

Landor is a brand consulting firm founded in 1941 by Walter Landor, who pioneered some research, design, and consulting methods that coined the phrase as we use today “branding”. Landor today still holds the core fundamentals of Walter Landors approaches but with some revolutionised practices to stay nimble and ahead of the technological curve. Landor is particularly well known for moving its headquarters onto a ferryboat called the ‘klamath’ docked in San Francisco Bay in 1964. The ferryboat being a crucial part of the consultancies history and story now forms part of Landor’s own branding.

Image Source: https://landor.com/

On June 18 2019 I was grateful to be shortlisted out of many applicants to attend a Landor assessment day. The day kicked off with everyone meeting at Landor’s amazing London offices, next to tower bridge. We watched a fantastic video reel showing the best of what Landor does! Representatives of Landor’s various departments and creative sectors then gave short presentations about what they each do and how they all collaborate with each other. These considered: Writing Copy, 3D/ animation and Experience Design, Graphics, Strategy and ‘Q’. It was really interesting to see how Landor structured itself and approached solving briefs through their diverse multidisciplinary teams and skillsets.

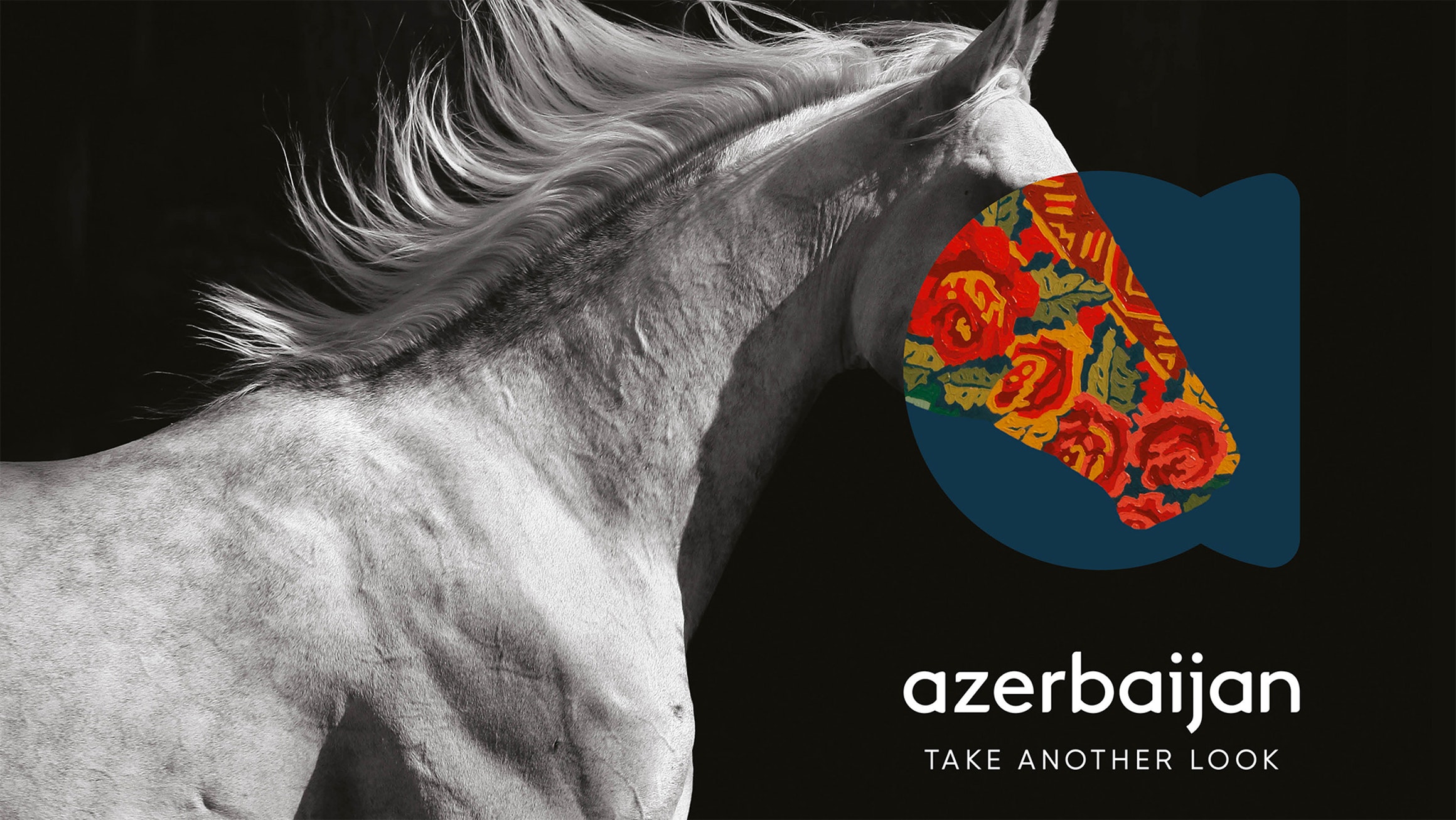

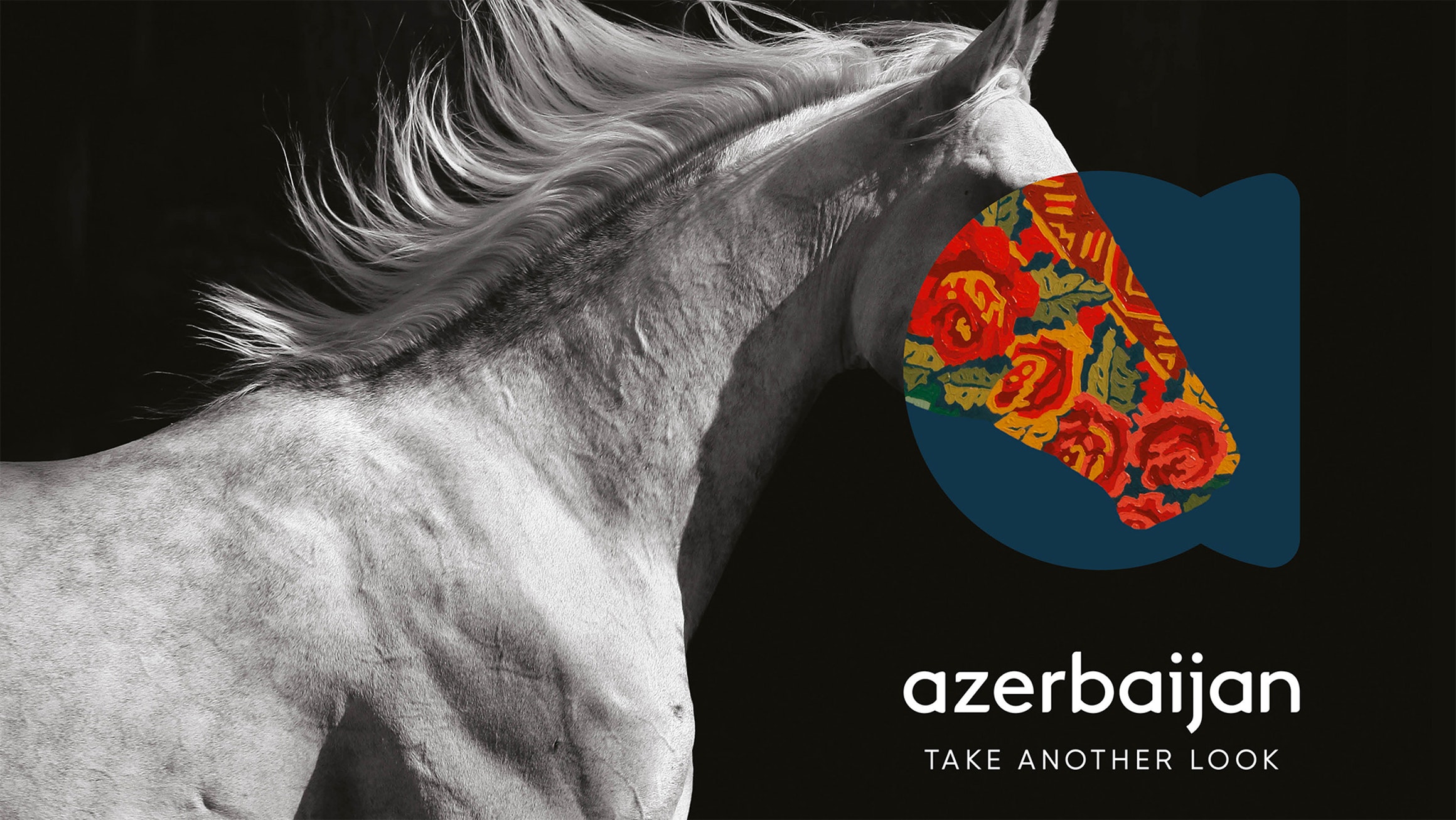

Azerbaijan

Landor recently “won multiple awards including Best Overall Visual Identity for Azerbaijan Tourism Board in a project that focused on redefining its brand with character, a strong point of view and a unique approach to copy style.” (https://landor.com/news/landor-scoops-18-accolades-transform-mena-2019-awards). Although the country is relatively well known to the Arab and Russian markets it is not to the rest of the world. Landors approach was to create a new identity which focuses on using the ‘a’ of Azerbaijan to act as a window or a lens, to open peoples eyes. When the ‘a’ formed out of a circle and semi-circle is overlapping imagery it shows a different perspective, point of view and depiction of the culture and environment. This is also supported by the phrase ‘Take another look’.

The lens shape is a symbolic peak into the “untold stories and secrets” of Azerbaijan, says Shaun Loftman, executive creative director at Landor EMEA (Europe, Middle East and Africa). Source

Image Source: https://landor.com/

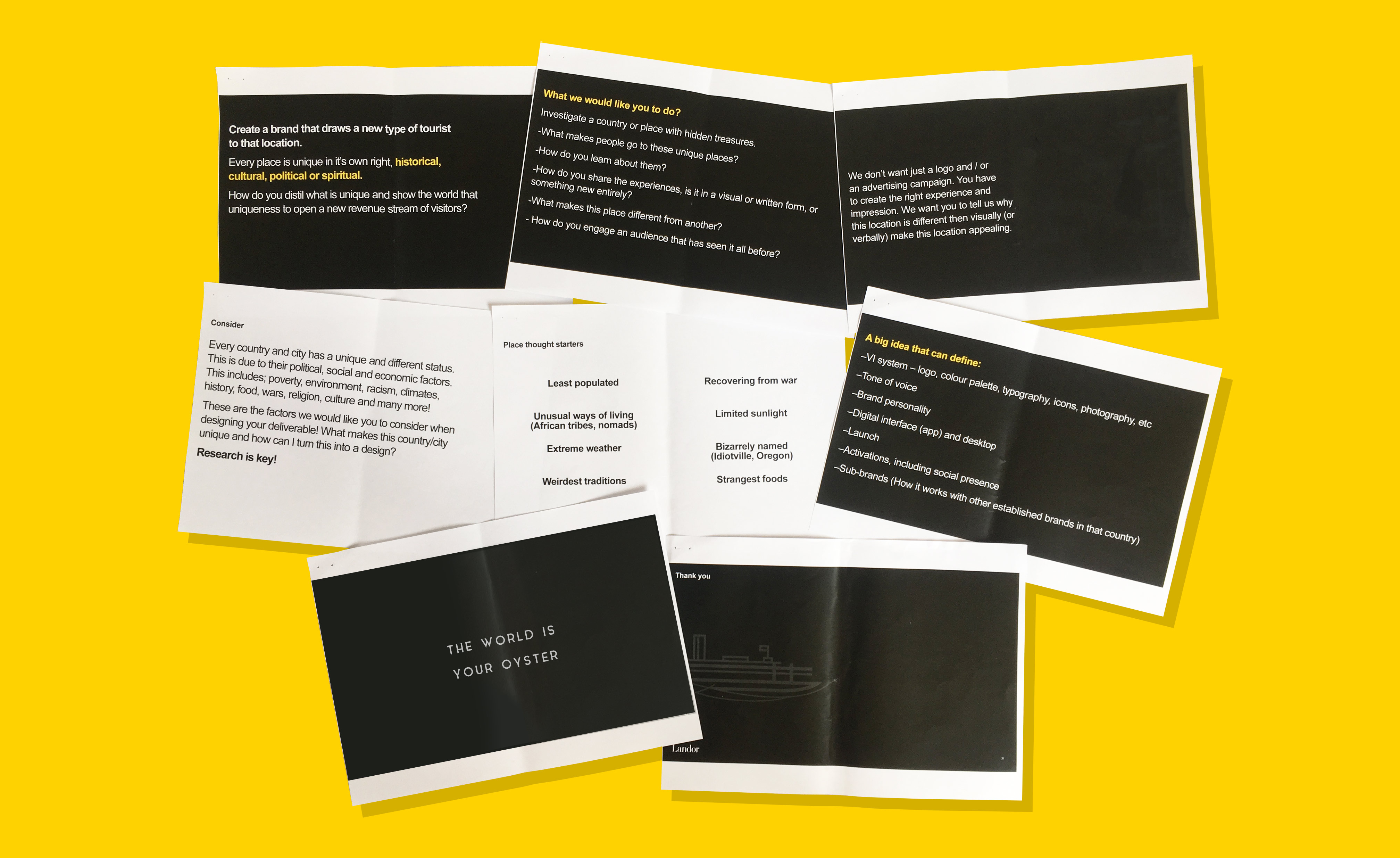

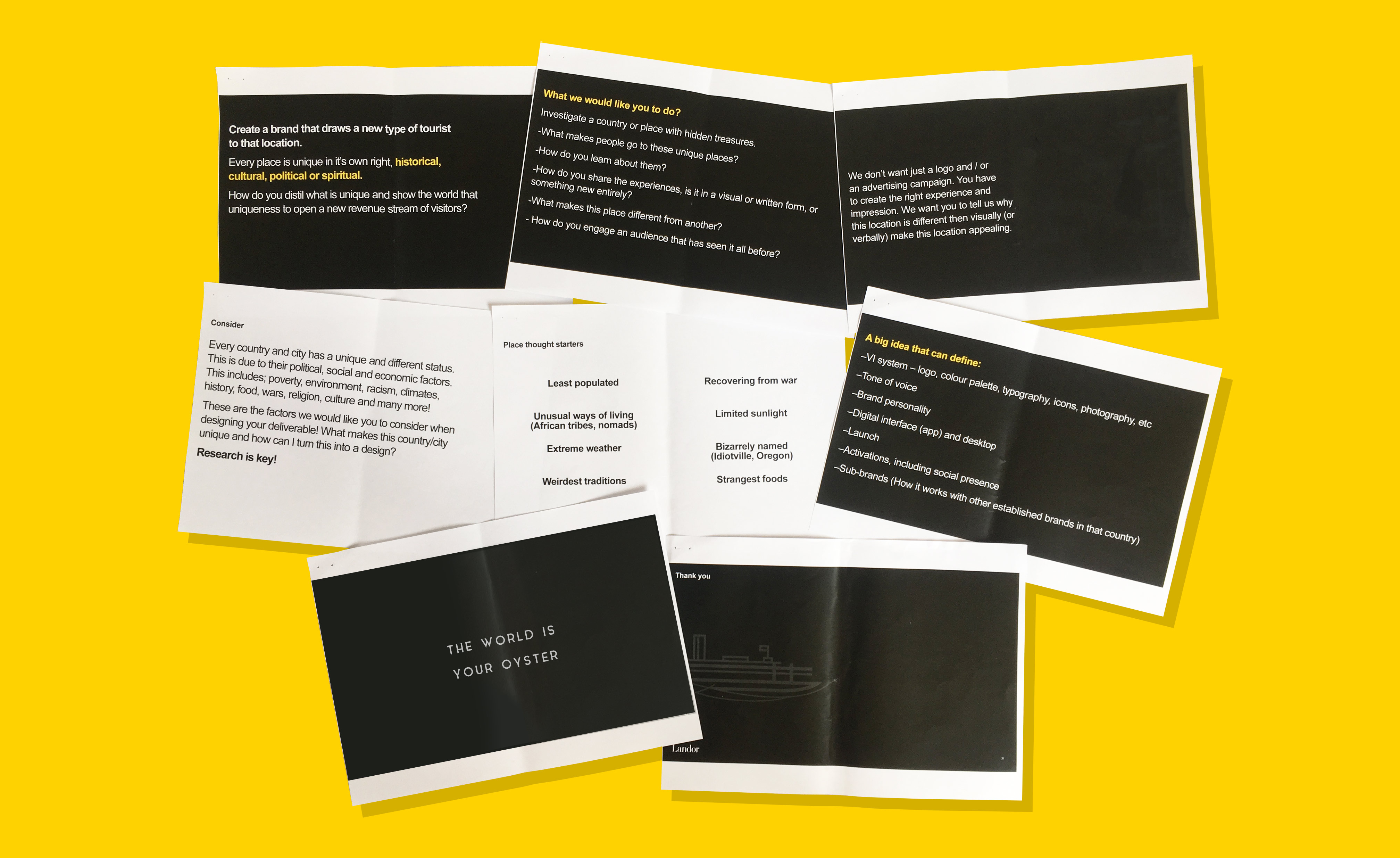

The Task

We were distributed into small teams with different skill sets and backgrounds. On my team was Sneha Goel (Graphic communication and illustration background), Jack McSwiney (Copywright and Advertising background) and Sunyang (Graphics Background) . We were tasked to choose a country that wasn’t accepted as a popular tourism destination or a place people would not necessarily think to visit, be it for cultural, environmental, geography, religious, war, economic or any other factors. The challenge: To create our own brand strategy that enlightens interest and tourism to a chosen country. The goal was to first understand key aversions to visit that place and then discover the hidden beauties, gems, and opportunities that could be highlighted upon to draw tourism in. There were many ways to approach this task under the time limit and the level of deliverables for the 15 minute presentation at the end of the day was down to our planning. The main focus was on showing our creative thinking, strategy, reasoning and a clear story during our presentation.

As a team we first approached the task having a brain storming session each going away, researching and presenting back options of countries we could move forward with. Countries that arose were Iceland for its cold, stark wilderness, and darkness. Estonia for being one of the least religious countries in the world. Laos next to Vietnam because it has just as much history and beauty, but can appear overshadowed by the tourism of Vietnam. Qatar because of similar reasons being overshadowed by the recently popularised tourism metropolis of Dubai. As well as its scorching heat, lack of tourism development, grid iron cities and religious restrictions. Many other ideas and countries arose and were discussed but nothing leaped out to the whole team as a key place to choose until we stumbled upon ‘Kiribati’. At which point we all said where’s Kiribati?!?

Kiribati is a sovereign state in Micronesia in the central Pacific Ocean.

The permanent population is just over 110,000. The state comprises 32 atolls and reef islands and one raised coral island, Banaba. They are dispersed over 3.5 million square kilometres. Their spread straddles both the equator and the 180th meridian, although the International Date Line goes round Kiribati and swings far to the east, almost reaching the 150°W meridian. This brings the Line Islands into the same day as the Kiribati Islands. Kiribati’s easternmost islands, the southern Line Islands, south of Hawaii, have the most advanced time on Earth: UTC+14 hours.

We found this incredible that this tiny country was spread over 4 hemispheres! Which drew us to look at its geographical location…

It would take 30 hours to get to Kiribati from UK and just as long from many other countries. This was our negative to key in on and explore how the countries remote location could be re-visualised as a worthy journey to make to visit the country. We chose Kiribati to move forward.

We needed to research and explore the country further.

Kiribati’s national flag: The frigatebird symbolises command of the sea, power, freedom and Kiribati cultural dance patterns, the blue and white wavy bands represent the pacific Ocean, which surrounds Kiribati and the sun refers to Kiribati’s position astride the Equator.

Environment:

The climate is pleasant from April to October, with predominant northeastern winds and stable temperatures close to 30 °C (86 °F). The islands consist of beautiful white sandy beaches, atolls and reefs. Most islands are uninhabited. The economy depends on subsistence farming, fishing, and the island’s prolific stands of coconut palms.

It is predicted by the United Nations Intergovernmental Panel on Climate Change that sea levels will rise by about 50 cm (20 in) by 2100 due to global warming . It is thus likely that within a century the nation’s arable land will become subject to increased soil salination and will be largely submerged. This means there is a limited time to visit the country!!

Language and Ethnicity:

The people of Kiribati speak an Oceanic language called Gilbertese. The native people of Kiribati are called I-Kiribati. Ethnically, the I-Kiribati are Micronesians.

Travel:

Since January 2009, Kiribati has had two domestic airlines: Air Kiribati and Coral Sun Airways. Both airlines are based in Tarawa’s Bonriki International Airport and serve destinations across the Gilbert Islands only. To get to the islands you would need to take connecting flights or travel by other means.

Culture,Dance & Music:

The uniqueness of Kiribati when compared with other forms of Pacific island dance is its emphasis on the outstretched arms of the dancer and the sudden birdlike movement of the head. The Frigate bird (Fregata minor) on the Kiribati flag refers to this bird-like style of Kiribati dancing. They also have a range of chants and tribal performances. The local ‘I-Kiribati’ also make tribal jewellery and Micronesian tattoo markings.

Things to Do:

‘Kiritimati’ island – a re-spelling of the english word ‘Christmas’ and is the worlds farthest forward timezone at UTC+14 and is one of the first inhabited places to experience New Year.

They pride themselves on their fly fishing opportunities, Lagoons, scuba diving, beaches and surfing. Incredibly colourful fish and WWII shipwrecks . The islands are so remote they are near were nuclear weapons used to be tested in the Pacific Ocean.

We also had a brief look at how the countries tourism board currently presents itself.

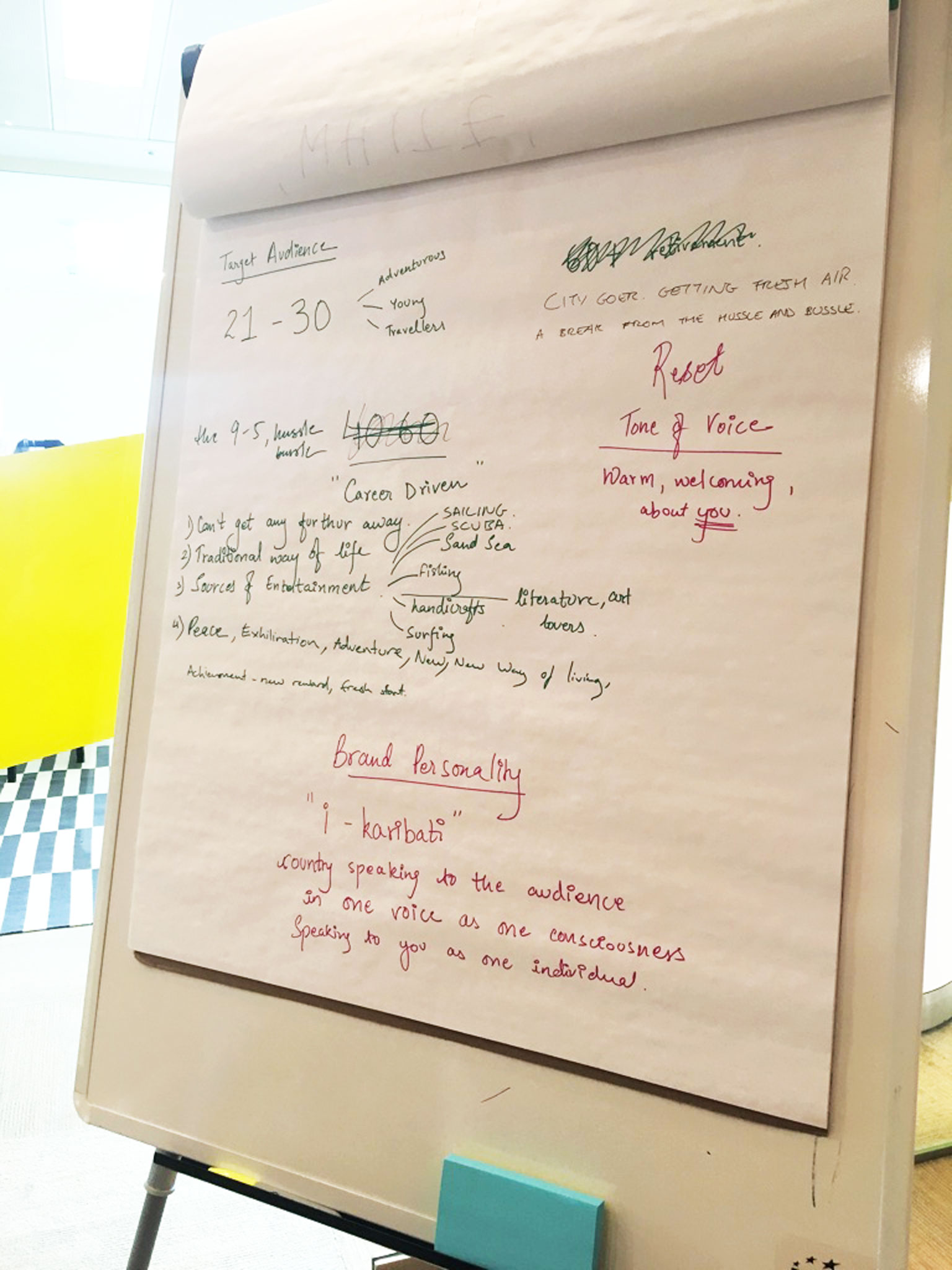

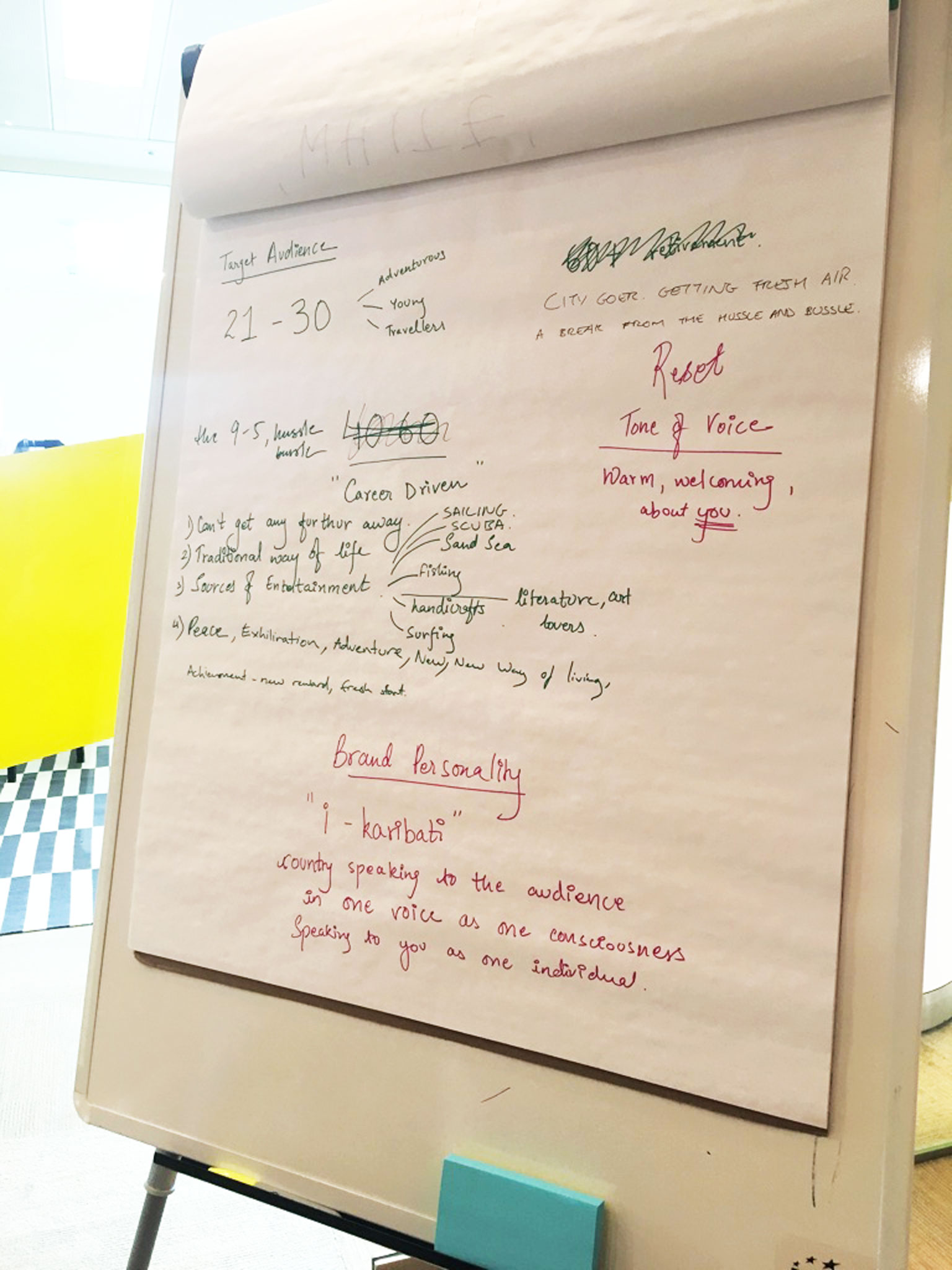

After collecting data on the country and all its natural beauty and culture, we had a clear understanding of the many positive values and experiences someone could gain by going there. We then decided to develop a persona and build a story for an ideal target ‘Tourist’ who would travel the many hours and miles to visit.

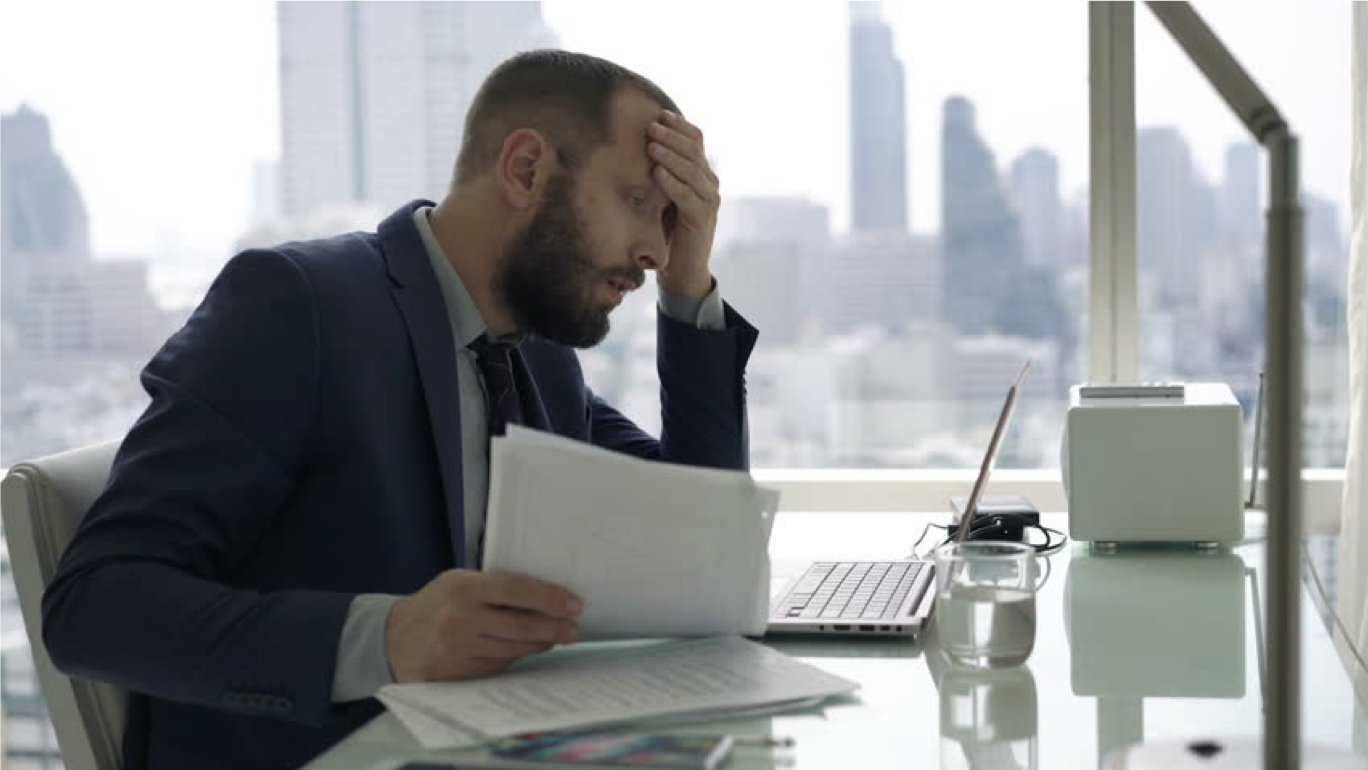

After creative deliberation we developed a character who was a young career driven city goer, early 30s. Who is becoming more senior in his role but is losing his work life balance and is becoming dragged down by the ‘hustle and bustle’ of ‘the 9-5’. They are passionate and still feel young but also have been able to make adventurous bold decisions to get to where they are in their successful career. It is at this point they feel they need a holiday that provides that feeling of adventure and a mild reset. A feeling of escape.

You cant get further away from where you are than by going to Kiribati. Both geographically and psychologically. Kiribati follows a traditional way of life bringing peace, exhilaration and adventure all together through living naturally with the Earths resources. We chose to switch around the perspective of the long journey, aiming to use it as a positive. Enjoy the exhilaration of the journey to then reap the rewards of your stay from simply relaxation or the multiple activities available within the countries natural culture . This became the development of our strategy and campaign we called ‘i-Kiribati’.

Utilising the phrase ‘i-Kiribati’ which the natives already call themselves we used this as the phrase for the campaign.

Discovering yourself but also being welcomed into a new culture, a new way of being, Discover Kiribati! “i- Kiribati”

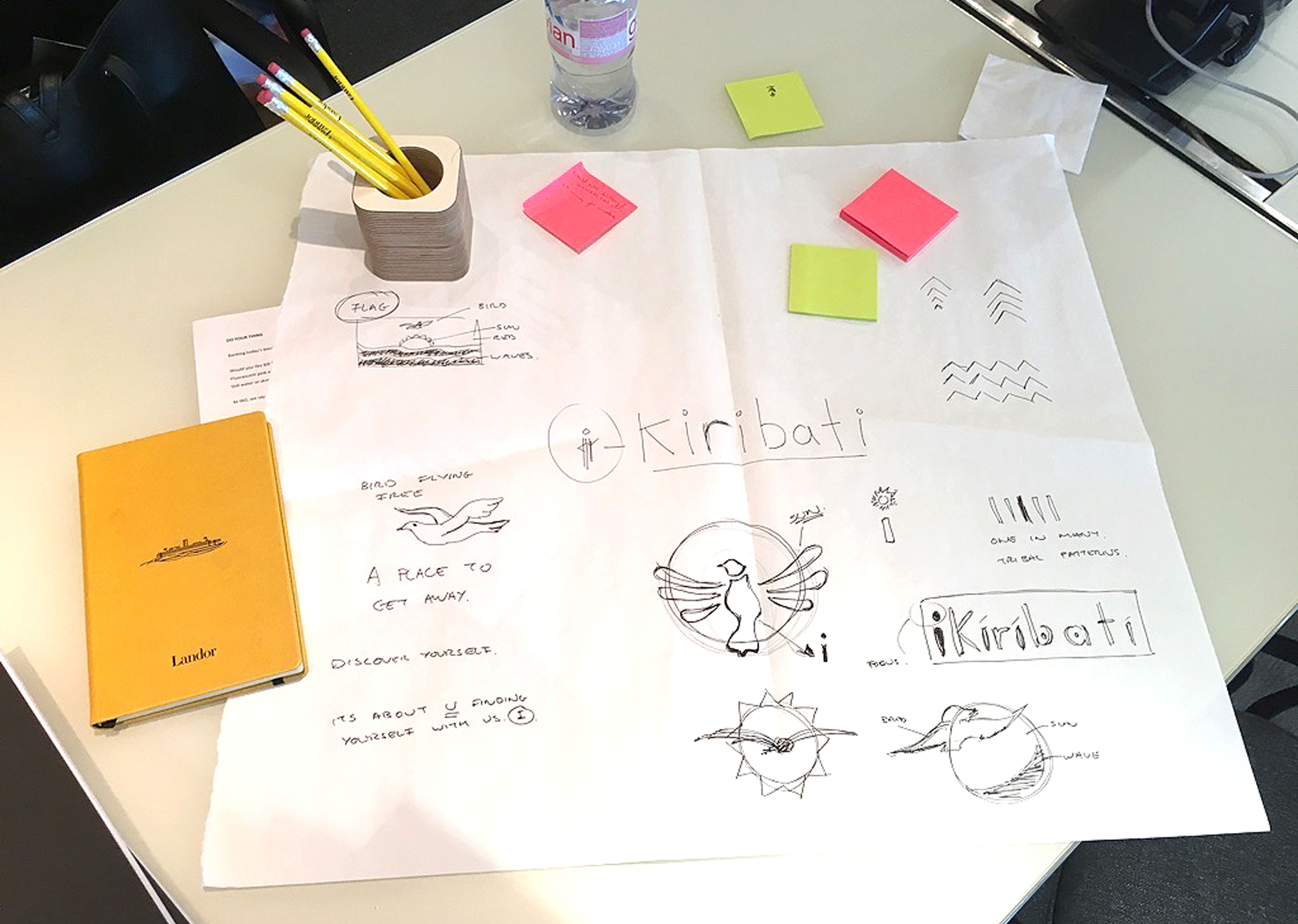

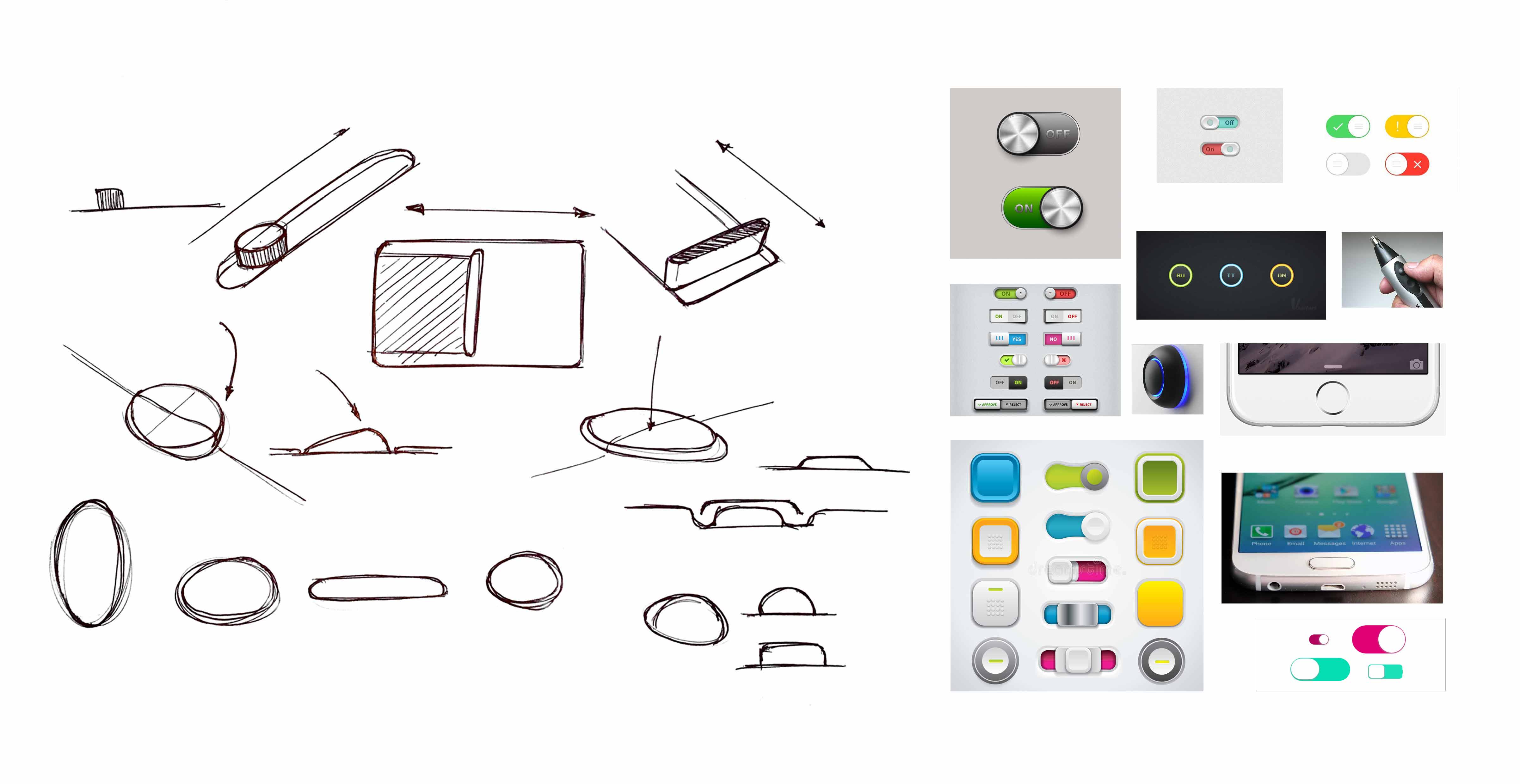

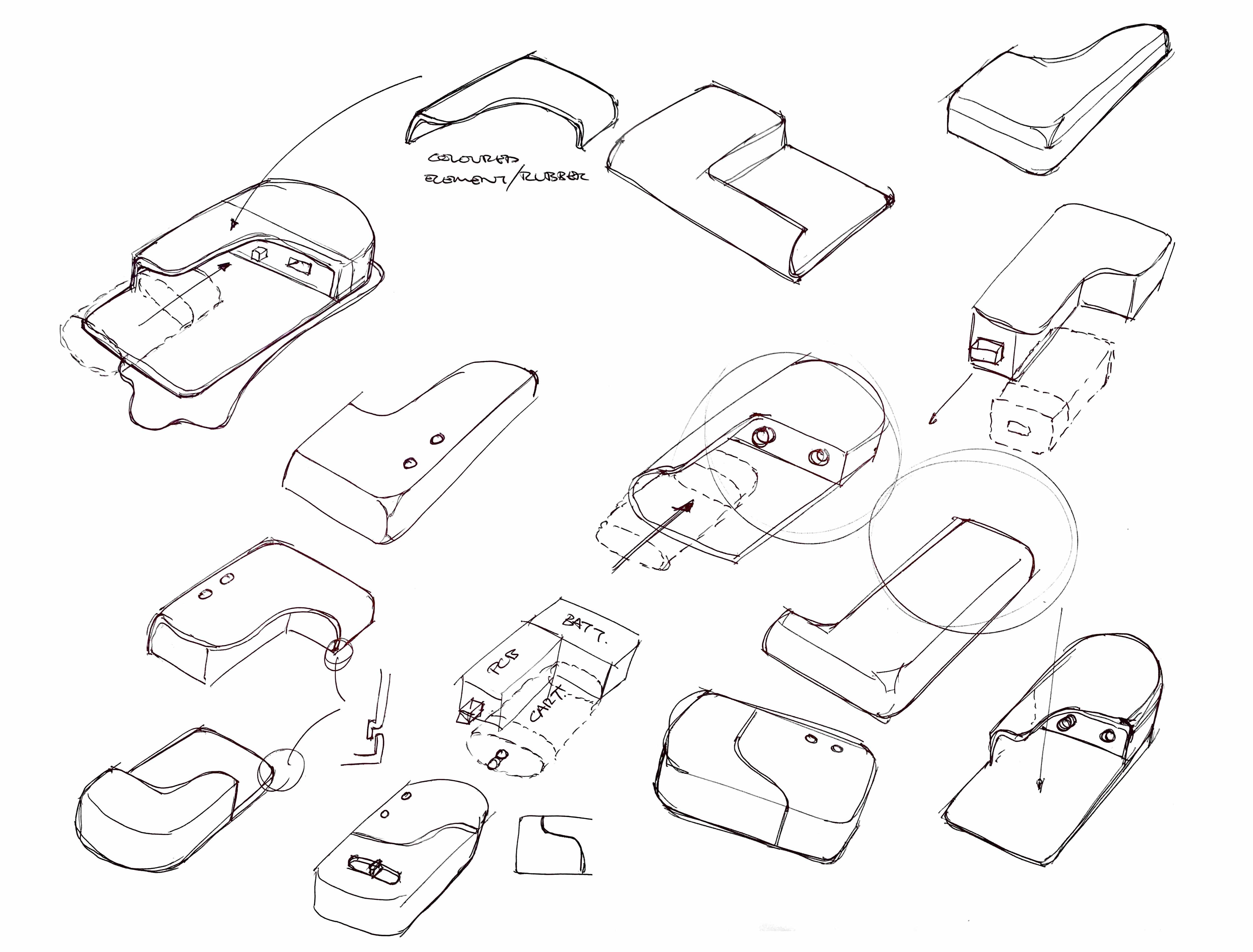

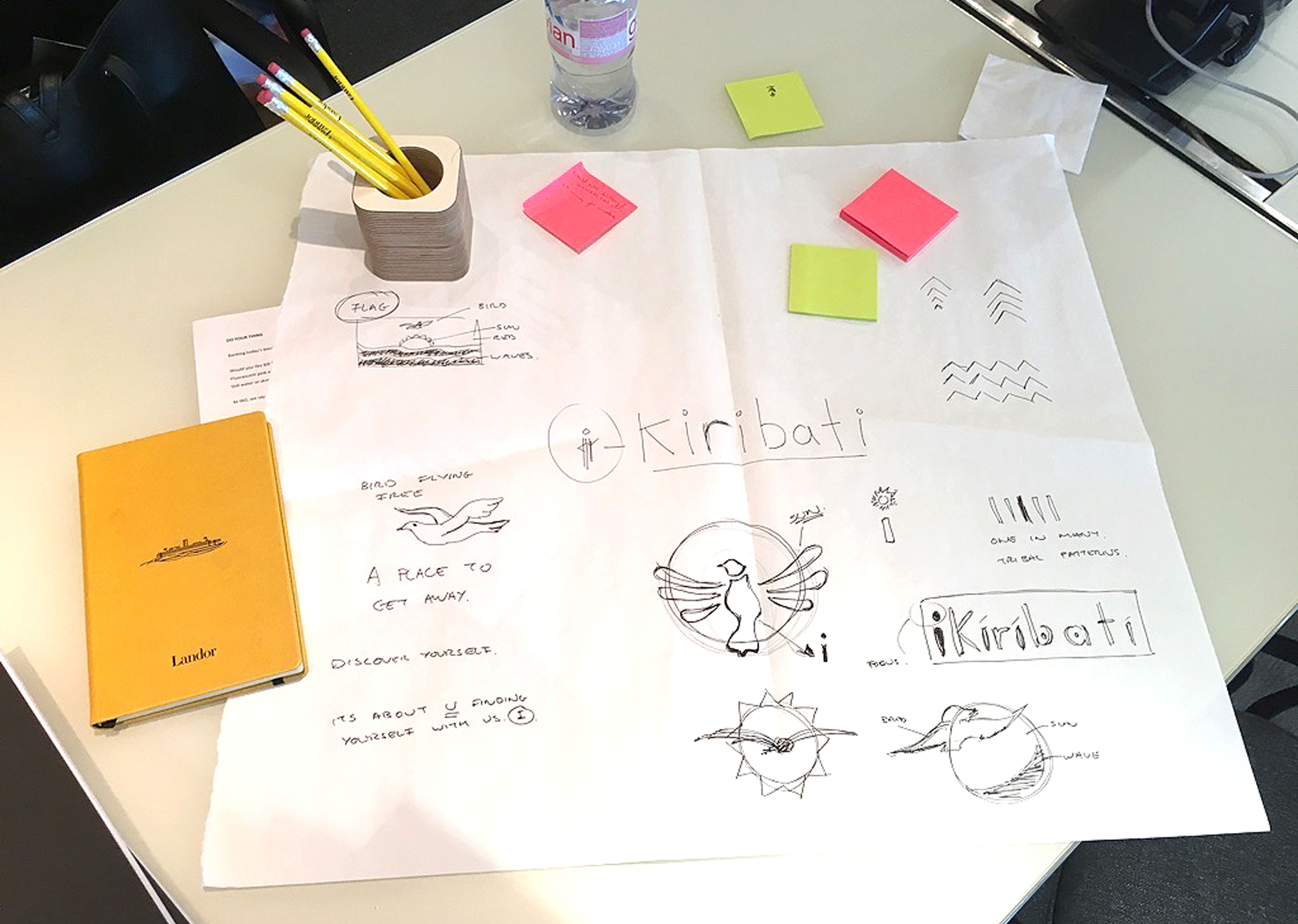

At this point, time was becoming quite strained but we had developed our strategy and presentation material. We then had a brief stint working on the identity. Relating back to the core values of the flag, we chose to explore what could be done with the bird, sun and sea. We played with the idea of the bird rising up/ flying free mimicking the shape value of the letter ‘i’ for ‘i-Kiribati’. The birds wings representing the flares of the sun. We also explored Micronesian patterns and tattoos thinking about how they can mimic the values of sun or sea and how an element of the pattern could be highlighted upon as individual within the entirety of the pattern (culture) . Thus relating to the discovery of yourself through visiting i-Kiribati. We also really liked the idea of utilising the unique value of being situated in 4 hemispheres and how that could be related to experiences for instance; land, sea, culture, freedom! During the presentation we discussed this and how that could be covered through some means of a dynamic logo- for instance imagery in the sun could cycle and change. There is a lot that could be developed with with further time and exploration that could definitely lead to a really exciting identity, mockups and visual outcome for the strategy.

The other teams presented their ideas for their countries such as Papua New Guinea and Saudi Arabia. Overall it was a really interesting day and enjoyable experience meeting and talking with people at Landor. It was also a pleasure working with everyone in my team and learning their approaches to thinking and working relative to their degree/ backgrounds. I believe our team was very successful and had a great outcome for the day.